Rear Subframes Made by Integrated Die Casting

The "2022 European Best Aluminum Die-cast Award Results" were announced, among which the "one-piece die-cast rear subframe" made by the German Hantmann company using die-cast technology won the first place.

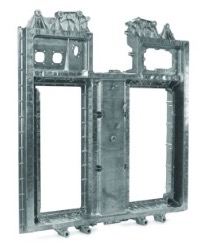

One-piece die-cast rear subframe made in Germany

Dimensions (length, width and height): 1260mmx670mmx390mm

Weight: 19300 grams

Alloy: AlSi 10MnMg

Descriptions of the product: it is functionally integrated. The connection points are used to install control arms, struts and stabilizers, electric drives, connect and fix components on the body. In particular, a closed cavity is created by the hollow profile integrated into the casting process in the die-cast process, meeting requirements for strength, stiffness and NVH. The overall design of TOP-HAT avoids complicated connection process and various single components.

Reasons for adopting die-cast process: The integrated die-cast design avoids complicated assembly steps such as the welding process. Different parts can be canceled. Machining can be performed in one setup. Thanks to the insert technology, weights are reduced while maintaining the same or better performance of the components. Therefore, the die-cast method has become the optimal and the most economical process.

The SP52 lower case made in Germany

Dimensions (LWH): 1258mm x 1152mm x 165mm

Weight: 30067 grams

Alloy: Al Si 10 Mn Mg

The description of the product: As the core component of the high-voltage storage system, the lower housing part must meet various requirements for good functions throughout its entire service life.

Requirements for design, casting, and molding: Typically, the die-cast housing for a high-voltage storage unit of this size is two-piece. This SP52 high-voltage storage unit is the first to use a one-piece die-cast design. In terms of molds, a two-plate solution was adopted because of its advantages in terms of circuit materials, optical casting and operation, mold weight and die-cast machine design. In the design of the mold, the following aspects are especially taken into consideration:

- Minimum amount of release agent applied

- Long runners in the mold

- Heat treatment of die castings

- Weldability of die castings

- Crashworthiness of die castings

- Requirements for dimensions of die castings

In addition, the tightness of the assembled HVS (no porosity in the machined housing flange) also plays an important role.

Reasons for adopting the die-cast process: The advantages of die-cast hybrid housings are as follows compared with traditional sheet metal structures:

- Reduced 16 single pieces

- The length of the sealing welding seam reduced by more than 50%

- Weight loss of 6 kg

- Significantly reducing manufacturing costs

Reasons for winning:

- A comprehensive method to obtain an economically optimal solution

- Integrated design

- Replacing 16 individual components, length and weight of sealing seam compared to sheet metal

- Long runners

- Parts related to collision

3498 casing and 3D printed samples made in Germany

Dimensions (LWH): 94 mm x 92 mm x 92 mm

Weight: 450 grams

Alloy: Al Si 12 (230)

The description of the product: Micro motors for signal acquisition are then mounted in four holes located on the long sides of 46 mm. The enclosure installed later must meet the requirements for sealing of IP56.

Reasons for the die-cast process: To ensure that there are no surface or structural defects, the thermal balance of the mold must be optimal, in addition to the pure casting parameters. This is not possible with conventional methods (classical tempering of the mold core). The quality of casting can be improved by using additively manufactured mold cores in the 3D printing process. In addition, the heat consumption of the mold is reduced and the cycle time is shortened.

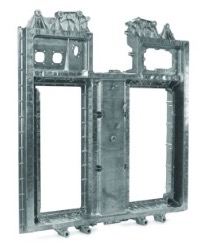

One-piece die-cast rear subframe made in Germany

Dimensions (length, width and height): 1260mmx670mmx390mm

Weight: 19300 grams

Alloy: AlSi 10MnMg

Descriptions of the product: it is functionally integrated. The connection points are used to install control arms, struts and stabilizers, electric drives, connect and fix components on the body. In particular, a closed cavity is created by the hollow profile integrated into the casting process in the die-cast process, meeting requirements for strength, stiffness and NVH. The overall design of TOP-HAT avoids complicated connection process and various single components.

Reasons for adopting die-cast process: The integrated die-cast design avoids complicated assembly steps such as the welding process. Different parts can be canceled. Machining can be performed in one setup. Thanks to the insert technology, weights are reduced while maintaining the same or better performance of the components. Therefore, the die-cast method has become the optimal and the most economical process.

The SP52 lower case made in Germany

Dimensions (LWH): 1258mm x 1152mm x 165mm

Weight: 30067 grams

Alloy: Al Si 10 Mn Mg

The description of the product: As the core component of the high-voltage storage system, the lower housing part must meet various requirements for good functions throughout its entire service life.

Requirements for design, casting, and molding: Typically, the die-cast housing for a high-voltage storage unit of this size is two-piece. This SP52 high-voltage storage unit is the first to use a one-piece die-cast design. In terms of molds, a two-plate solution was adopted because of its advantages in terms of circuit materials, optical casting and operation, mold weight and die-cast machine design. In the design of the mold, the following aspects are especially taken into consideration:

- Minimum amount of release agent applied

- Long runners in the mold

- Heat treatment of die castings

- Weldability of die castings

- Crashworthiness of die castings

- Requirements for dimensions of die castings

In addition, the tightness of the assembled HVS (no porosity in the machined housing flange) also plays an important role.

Reasons for adopting the die-cast process: The advantages of die-cast hybrid housings are as follows compared with traditional sheet metal structures:

- Reduced 16 single pieces

- The length of the sealing welding seam reduced by more than 50%

- Weight loss of 6 kg

- Significantly reducing manufacturing costs

Reasons for winning:

- A comprehensive method to obtain an economically optimal solution

- Integrated design

- Replacing 16 individual components, length and weight of sealing seam compared to sheet metal

- Long runners

- Parts related to collision

3498 casing and 3D printed samples made in Germany

Dimensions (LWH): 94 mm x 92 mm x 92 mm

Weight: 450 grams

Alloy: Al Si 12 (230)

The description of the product: Micro motors for signal acquisition are then mounted in four holes located on the long sides of 46 mm. The enclosure installed later must meet the requirements for sealing of IP56.

Reasons for the die-cast process: To ensure that there are no surface or structural defects, the thermal balance of the mold must be optimal, in addition to the pure casting parameters. This is not possible with conventional methods (classical tempering of the mold core). The quality of casting can be improved by using additively manufactured mold cores in the 3D printing process. In addition, the heat consumption of the mold is reduced and the cycle time is shortened.

Related News

- Impact of Heat Treatment on Mechanical Properties and Thermal Conductivity of ZL102 Alloy

- Impact of T6 Heat Treatment on ADC12 Aluminum Alloy Properties

- Enhancing the Mechanical Properties of ADC12 Aluminum Alloy via T6 Heat Treatment

- Die-Casting Process Design of Valve Bodies for Automobile Oil Cylinder Parts

- Temperature Field Simulation & Optimization of Automotive Housing Die Castings

- Research Status of High-Impact Aluminum Alloys Domestically and Internationally

- Die-cast Aluminum Castings for High-speed Rail Rocker Arm Shells

- Aluminum Alloys for Automobile Body Panels

- Analysis and Measures of Internal Shrinkage Cavities in Aluminum Die Castings

- Advantages of Aluminum Alloys in Lightweight Automobiles