Measures of Leakages of Aluminum Die Castings (Part One)

From the aspects of the structure of die-cast molds, analysis of mold flows and production process, the measures for leakages caused by common defects such as shrinkage cavities and damage to surfaces of die castings are introduced in detail. Practice shows that the risk of the leakage of die-cast aluminum parts is effectively reduced by this method, and the internal quality of die-cast aluminum parts is improved.

The application of die-cast aluminum parts to automobile engines is more and more extensive, such as cylinder blocks, covers, oil pans, etc., but there are also many problems, one of which is leakage. Typically, the foundry will roughly machine the blank, and then use compressed air to perform a 100% leakage test on the part. The common method is the differential pressure method or the volume flow method. The qualified parts are to the OEM. The OEM performs precision machining, and the casting defects of the die-cast parts will be exposed on the machined surface. Many appearance defects are screened by visual inspection, but the parts will still be screened by a 100% leakage test. A 100% leakage test is also performed for different channels such as oil channels and cooling water channels. In the end, various leaks will still occur in the function test of the engine and the whole vehicle and even the user's use process. The reason is that many little leaks cannot be detected during the cold leakage test of the parts and the engine. However, during the actual operation of the engine, the oil temperature can reach 120°C and the problem will be exposed, which brings greater risks of quality to die casting manufacturers and OEMs. Therefore, how to reduce or avoid this quality problem has become a research topic for researchers.

1. Confirmation of the cause of leakages

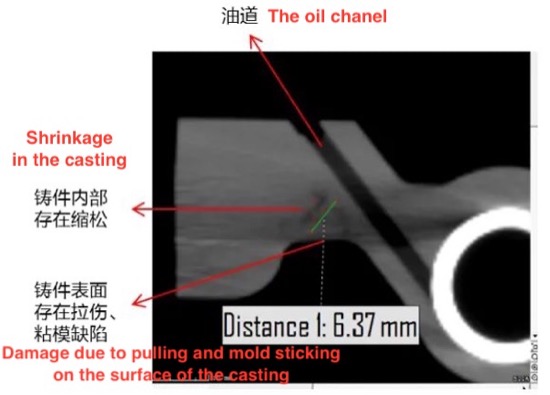

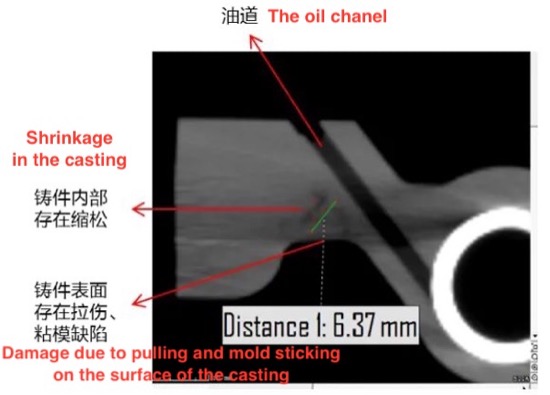

Technicians use various tools to confirm the cause of the leakage, and simple visual inspection and professional water testing equipment are adopted to confirm the leak point. Perform CT inspection or color development flaw detection on the parts to confirm the leakage channel, and slice for metallography analysis finally. At present, the main reason for leakages is that there is shrinkage porosity inside the casting, and the size of the shrinkage porosity varies from tens of μm to several mm. At the same time, there are damage and mold sticking on the surface of the casting. The combination of the two forms a channel that expands further when the oil or coolant temperature is high, resulting in leakages of oil or coolant. (Figure 1)

Figure 1 Leakages of oil in aluminum die casting during the engine test (damage to the surface after visual inspection, internal shrinkage porosity after CT scan)

2. Measures to shrinkage porosity and mold sticking

A solution to leakages of die castings is summarized from the aspects of mold or product structure, analysis of mold flows, formulation of process parameters, process control and inspection of products and effective prevention of leakages are explained.

2.1 The analysis of mold temperatures and mold flows

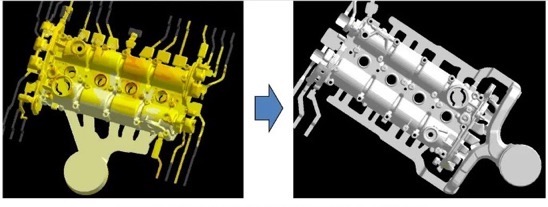

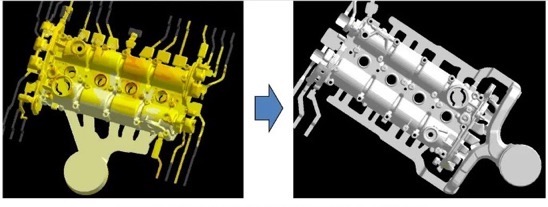

A certain cylinder head cover had several little leaks during the engine test. The location of the leakage was not fixed, but they were all close to the side of the pouring gate. At the same time, mold sticking and damage occur on the surface. In the actual production process, it was found that cracks, mold sticking and damage began to appear near the pour gate of the new mold. No abnormality was found in the inspection of mold materials, surface treatment and mold temperatures. When the analysis of the mold flow was performed again, it was found that with the existing mold design, the cross-sectional area of the pouring gate was small, and the mold was seriously scoured by molten aluminum. In this regard, the mold was redesigned, the pouring gate was optimized, and the single-sided runner was replaced with a double-sided runner (Figure 2), thereby increasing the cross-section of the pouring gate and reducing the scouring of the mold by the molten aluminum. Fundamentally solved the problem.

Figure 2 Optimization of molds of cylinder head covers (replacing single-sided runners with double-sided runners)

When designing a mold, it is usually necessary to use professional software to analyze the mold flow and mold temperature of the mold to identify whether there is air entrainment in the filling process of the molten aluminum, whether the cross-sectional area of the pouring gate is reasonable, and to determine the final cooling position of the part forming process to reasonably design the process and properly optimize the mold structure. Therefore, attention should be paid to the simulation analysis. First, the consistency of the mold and the entity, and at the same time, the cooling channels and pouring risers inside the mold need to be fully considered. Second, the mesh division affects the accuracy of the simulation analysis. The type and number of meshes need to be considered when meshing, and the mesh changes with the distribution of the wall thickness of the part. Third, the accuracy of the material data of the molten aluminum needs to consider the thermal expansion coefficient, shrinkage rate and viscosity of the material when setting the material properties. Fourth, the process parameter settings also need to be consistent with the actual situation, such as mold temperatures, aluminum liquid filling temperatures, pressure holding curves, filling control methods, die casting parameters, etc.

The application of die-cast aluminum parts to automobile engines is more and more extensive, such as cylinder blocks, covers, oil pans, etc., but there are also many problems, one of which is leakage. Typically, the foundry will roughly machine the blank, and then use compressed air to perform a 100% leakage test on the part. The common method is the differential pressure method or the volume flow method. The qualified parts are to the OEM. The OEM performs precision machining, and the casting defects of the die-cast parts will be exposed on the machined surface. Many appearance defects are screened by visual inspection, but the parts will still be screened by a 100% leakage test. A 100% leakage test is also performed for different channels such as oil channels and cooling water channels. In the end, various leaks will still occur in the function test of the engine and the whole vehicle and even the user's use process. The reason is that many little leaks cannot be detected during the cold leakage test of the parts and the engine. However, during the actual operation of the engine, the oil temperature can reach 120°C and the problem will be exposed, which brings greater risks of quality to die casting manufacturers and OEMs. Therefore, how to reduce or avoid this quality problem has become a research topic for researchers.

1. Confirmation of the cause of leakages

Technicians use various tools to confirm the cause of the leakage, and simple visual inspection and professional water testing equipment are adopted to confirm the leak point. Perform CT inspection or color development flaw detection on the parts to confirm the leakage channel, and slice for metallography analysis finally. At present, the main reason for leakages is that there is shrinkage porosity inside the casting, and the size of the shrinkage porosity varies from tens of μm to several mm. At the same time, there are damage and mold sticking on the surface of the casting. The combination of the two forms a channel that expands further when the oil or coolant temperature is high, resulting in leakages of oil or coolant. (Figure 1)

Figure 1 Leakages of oil in aluminum die casting during the engine test (damage to the surface after visual inspection, internal shrinkage porosity after CT scan)

2. Measures to shrinkage porosity and mold sticking

A solution to leakages of die castings is summarized from the aspects of mold or product structure, analysis of mold flows, formulation of process parameters, process control and inspection of products and effective prevention of leakages are explained.

2.1 The analysis of mold temperatures and mold flows

A certain cylinder head cover had several little leaks during the engine test. The location of the leakage was not fixed, but they were all close to the side of the pouring gate. At the same time, mold sticking and damage occur on the surface. In the actual production process, it was found that cracks, mold sticking and damage began to appear near the pour gate of the new mold. No abnormality was found in the inspection of mold materials, surface treatment and mold temperatures. When the analysis of the mold flow was performed again, it was found that with the existing mold design, the cross-sectional area of the pouring gate was small, and the mold was seriously scoured by molten aluminum. In this regard, the mold was redesigned, the pouring gate was optimized, and the single-sided runner was replaced with a double-sided runner (Figure 2), thereby increasing the cross-section of the pouring gate and reducing the scouring of the mold by the molten aluminum. Fundamentally solved the problem.

Figure 2 Optimization of molds of cylinder head covers (replacing single-sided runners with double-sided runners)

When designing a mold, it is usually necessary to use professional software to analyze the mold flow and mold temperature of the mold to identify whether there is air entrainment in the filling process of the molten aluminum, whether the cross-sectional area of the pouring gate is reasonable, and to determine the final cooling position of the part forming process to reasonably design the process and properly optimize the mold structure. Therefore, attention should be paid to the simulation analysis. First, the consistency of the mold and the entity, and at the same time, the cooling channels and pouring risers inside the mold need to be fully considered. Second, the mesh division affects the accuracy of the simulation analysis. The type and number of meshes need to be considered when meshing, and the mesh changes with the distribution of the wall thickness of the part. Third, the accuracy of the material data of the molten aluminum needs to consider the thermal expansion coefficient, shrinkage rate and viscosity of the material when setting the material properties. Fourth, the process parameter settings also need to be consistent with the actual situation, such as mold temperatures, aluminum liquid filling temperatures, pressure holding curves, filling control methods, die casting parameters, etc.

Related News

- Impact of Heat Treatment on Mechanical Properties and Thermal Conductivity of ZL102 Alloy

- Impact of T6 Heat Treatment on ADC12 Aluminum Alloy Properties

- Enhancing the Mechanical Properties of ADC12 Aluminum Alloy via T6 Heat Treatment

- Die-Casting Process Design of Valve Bodies for Automobile Oil Cylinder Parts

- Temperature Field Simulation & Optimization of Automotive Housing Die Castings

- Research Status of High-Impact Aluminum Alloys Domestically and Internationally

- Die-cast Aluminum Castings for High-speed Rail Rocker Arm Shells

- Aluminum Alloys for Automobile Body Panels

- Analysis and Measures of Internal Shrinkage Cavities in Aluminum Die Castings

- Advantages of Aluminum Alloys in Lightweight Automobiles